Wilop Forge and Foundry have invested heavily in natural-gas heating furnace and modern hydraulic forging facilities to enable us to make finest forgings, while maintaining the clean air and safety. Using CNC vertical turning lathes, horizontal machining center and gantry lathes, WILOP is able to provide a host of precision machining processes.

-

Heating Furnace

Advanced natural-gas furnaces and heating system

Krom SIC high-speed burner pulse heating technology

Siemens S7-300 series PLC automatic temperature control

The highest temperature: 1200℃

-

Forging

Broad range of raw materials including special alloys

Open and closed die forgings – standard, specialized and custom

Seamless ring rolling machines

Weighting up to 50,000. Pounds

-

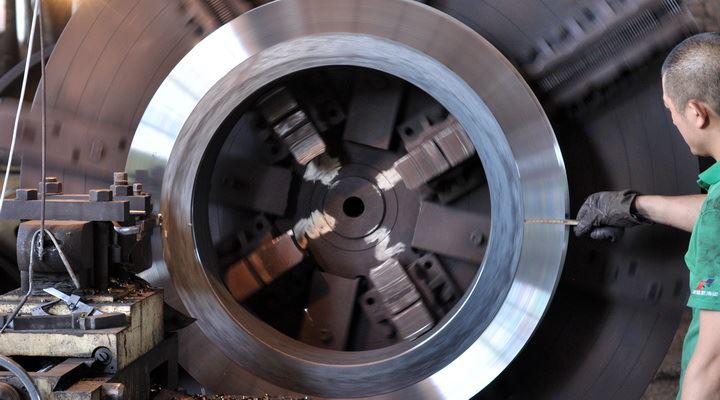

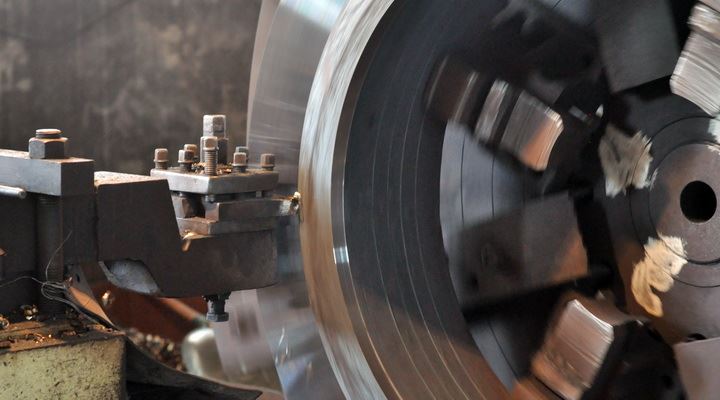

Machining

From rough machined to finished components

Gantry Lathes

CNC vertical turning lathes, gantry lathes

Horizontal machining center

-

Heat Treatment

Advanced in-house heat treatment capabilities

Normalizing

Water quenching

Tempering, Annealing

Stress relief

-

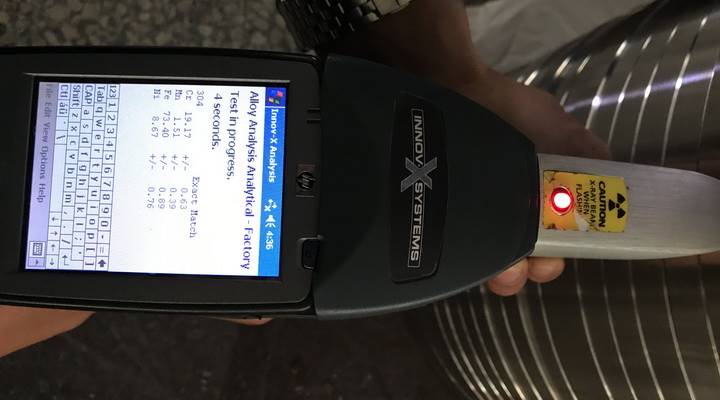

Testing and Inspection

Mechanical Testing – Tensile, Impact & Hardness

Chemical analysis

Charpy Impact testing

Destructive Exam Testing

Non-destructive Testing – UT, MPI and LPI